We are an innovative company that invests in continuous technology and application development. Therefore, we decided to participate in a number of interesting research projects, such as UKP2micron, FLASH and MIRACLE to foster customer and application-oriented development of our beam shaping technology.

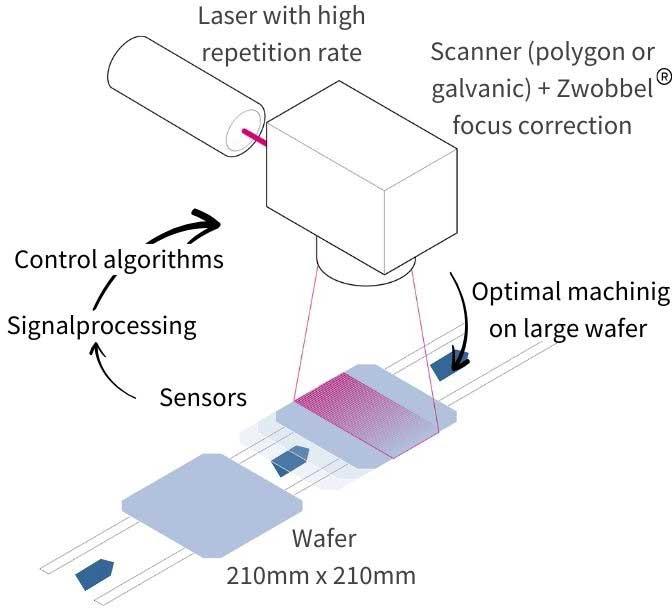

MIRACLE targets high-throughput microablation for electroplating next-generation solar cells. These cells need laser structuring innovations for:

✅ higher resolution for smaller traces,

✅ larger processing field for growing wafer formats, and

✅ faster beam deflection for shorter process times.

We increase the speed of our driving electronics and research novel control algorithms for our technology. Moreover, we elaborate our wavelength capabilities into the blue wavelength range for smaller traces. The therefore developed Zwobbel blue opens completely new applications not only in solar cell structuring but also in e-mobility.

As MIRACLE targets high-throughput applications, the solutions are based on ultra-fast scanners, new optical freeform designs, active focus correction, fast control, and high-bandwidth networking of components. Here, everything must work at top-speed for a successful project.

Consortium partners: LPKF SolarQuipment GmbH, Asphericon, RAYLASE, RENA Technologies GmbH. Project leader: Fraunhofer-Institut für Solare Energiesysteme ISE.

This RUBIN Project UKP2micron is a SME-driven alliance that develops processes and components for ultra-short, pulsed lasers. The consortium joints up to become the go-to supplier of ultrashort-pulse laser solutions in the spectral range of 1 μm and 2 μm. The alliance consists of 14 companies, two research institutions, and seven associated partners.

Our technology will transfered to 2um wavelength range and tested in various application such as addistive manufacturing, and fine structuring of bridle materials and glass. Please check the webpage www.ukpino.com and www.innovation-strukturwandel.de for more information.

Project Overview: Advancing Manufacturing

The FLASH project aims to develop a multi-process laser-machine tool for precise thermal and ablation-based processes on various materials. It combines multiple beams for versatility, reduces manufacturing time, waste, defects, and energy consumption. The project focuses on optimizing industry processing strategies, providing predictive capabilities, and considering environmental impacts throughout the product lifecycle to support Europe’s green and digital transition goals. Please follow us on LinkedIn and read our project page flashlaserproject.eu

This will be achieved by combining multiple beams that will be deliverable, in any combination, to the delivery systems. It will allow a single versatile machine tool to replace up to three separate machine tools, with full material and process flexibility. In addition, it will deliver an unprecedented level of manufacturing line agility, by enabling the reconfiguration of processes through the automated changeover of the laser beam delivery system in just seconds, compared to the several hours needed to replace or reconfigure traditional mechanical or laser machines. This highly precise type of manufacturing reduces waste, defects and energy consumption, leading to more successful and sustainable products.

The FLASH project will aim to deliver a fully optimized processing strategy for the industry. Considering all processes and parameters available to the FLASH machine platform, the process design package will identify the best sequence of individual processing steps and provide optimized parameters for each (e.g., tool path, power, pulse length, beam shape, spatial coherence, etc.). In contrast with existing modeling solutions, FLASH will deliver predictive capabilities for manufacturing. This will enable non-expert users, including SMEs, to rapidly develop new processes during accelerated product and process development cycles. The FLASH process design platform will also integrate a digital decision model that considers environmental impact indicators in two categories:

This robust focus on lifecycle environmental impact will be unprecedented in laser-based manufacturing process design, helping to drive the European industry’s green and digital transition goals.

Our project partners:

ROBUST AO GmbH

Hans-Knöll-Straße 6

D-07745 Jena

Germany

E-Mail: info@robustao.de