The Zwobbel System consist of the 3 Parts Zwobbel®-mirror, Zwobbel®Drive and Zwobbel®Control and some additional cables. The following is short explanation about the assembly of the entire system. A very detailed a step-by-step explanation is delivered with the system:

Q: Hi Stefan, thank you for taking your time. You have more than 15 years experience in laser machining and you are responsible for all application experiments here at ROBUST AO. So you do quite frequently Zwobbel oscillation parameter optimization. So as an expert: What do you need to consider when optimising parameters?

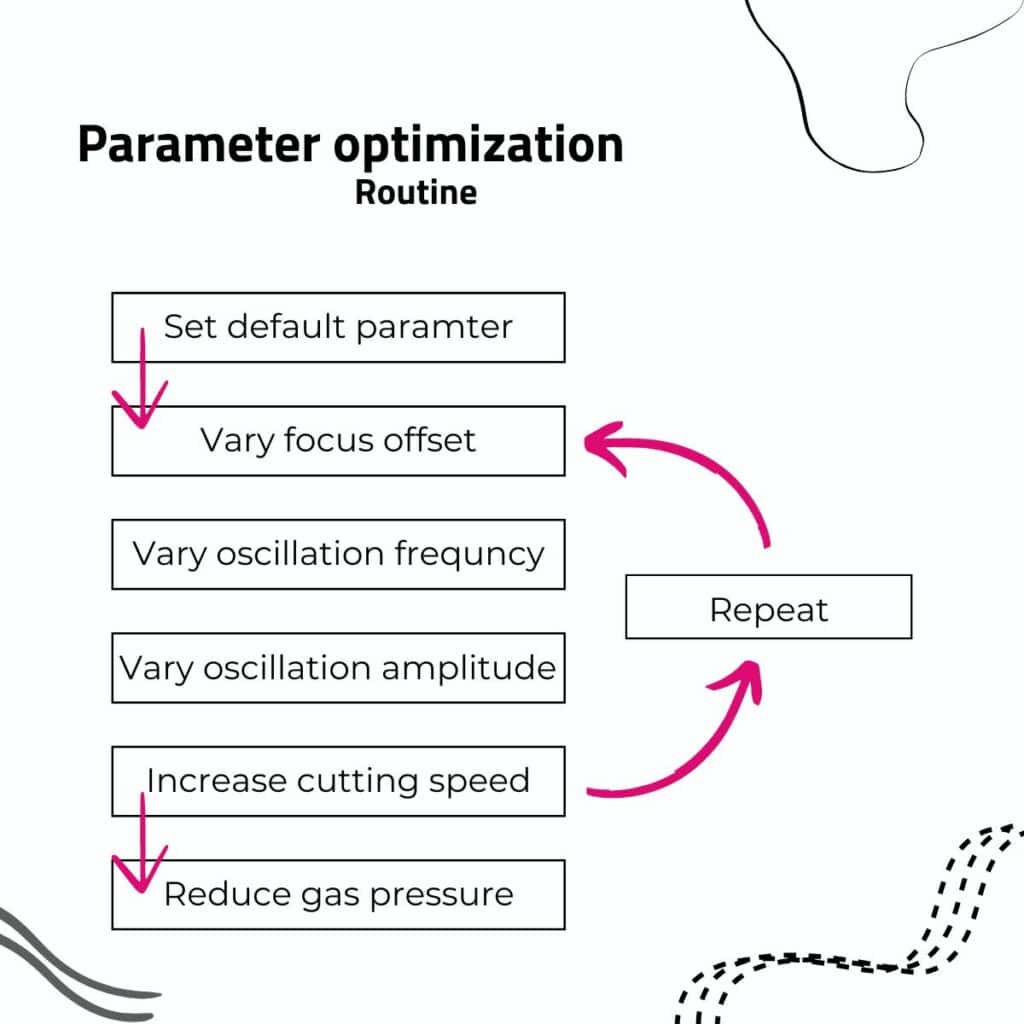

S: That’s an interesting question. At the beginning, we always tried to start with the static parameters (i.e. without focus oscillation) and then run through the parameter fields typical for Zwobble: Oscillation frequency, amplitude and offset (z-position).

However, the aim is to cut faster and increase the quality of the cut edge. For this reason, the Zwobbel parameters are inherently different. The focus is shifting constantly, and the speed is greater. So the static parameters are obsolete.

Q: OK, that makes sense when you think about it. So how do you make it better?

S: I set a default parameter set for the Zwobbel and vary the focus position to find an optimum

Q: Wait, what is Zwobbels default parameter set?

S: For me it’s 1kHz oscillation frequency and an oscillation amplitude of 50% of the Rayleigh length of the laser application. I always set the focus offset to 50% in order to have all the freedom I need. I use the static focus position of the machine system to place the offset roughly in the typical machining range (in the sheet during fusion cutting and above the sheet during flame cutting)

Q: Ok, got that and what happens next?

S: Now I vary the focus position, then vary the frequency and finally the amplitude. I do this optimisation until I like the processing result.

Then I increase the cutting speed. I always have to adjust the frequency and amplitude slightly. But that’s easier once I’ve reached an optimum.

Q: Great and then you’re done.

S: To play out the capability of the Zwobbel-technology, I then reduce the gas pressure. I can do this until the quality of the cut decreases. Fortunately, we usually need 40%-60% less gas compared to the static processes.

Q: Thank you Stefan, that will certainly help our customers!

ROBUST AO GmbH

Hans-Knöll-Straße 6

D-07745 Jena

Germany

E-Mail: info@robustao.de